There are a number of geometric considerations as well. Of course the size of the manufacturer’s equipment is a starting point, the length and width of the mother-glass it was designed to take. LCD fabrication equipment (fabs) comes in generations or gens. Early on, the gen of a fab did describe when it was made. However as the size of LCDs diversified with the types of products using flat panels, gen has taken on a meaning more related to the size of the equipment than when it was produced. An LCD maker may install a Gen 6 fab to make monitors and the fab may be newer than their Gen 8 fab making TVs. Within a Gen, sizes may vary somewhat; a slightly large Gen 6 fab may be termed a Gen 6.5. As with all manufacturing equipment, products change, screen sizes change, and a fab will eventually be making a different product in a different size from what it was originally designed for.

Aspect ratio is another consideration. TVs are generally 16:9. Notebooks may be 16:9 or 16:10. Cell phones and monitors can have substantial variances from square to 21:9. In addition to the display itself, a small border area is needed to cut the mother-glass into individual displays. The size of this border depends on the manufacturer. Finally, LCDs are usually made with all the displays on one mother-glass being the same type. The arrangement of these displays on the mother-glass is termed the lay-up. The layup does not necessarily use every square inch of glass, in fact usually not. However, makers like to maximize glass utilization from the standpoint of getting the most out of their equipment and maximizing the number of cuts.

Sometimes very small differences in equipment or display size can mean the difference between getting an extra cut or two. For instance, when the Standard Panels Working Group (SPWG) settled on a business notebook size of 16:10, 14.1” diagonal vs. the competing 15:9 14.0”, two sizes that cannot be differentiated except by actually measuring them, there were substantial manufacturing implications. While all of the fabs that could make a 14.1” could make the 14.0” as well, two of the fabs that could make a 14.0” could not make the 14.1” without making it with fewer cuts. This meant that those fabs were uneconomic at that size. The 14.1” size was chosen to be consistent with previous aspect ratios and with the long term planning for Windows regarding screen content.

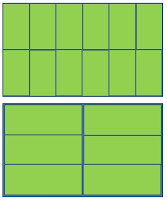

So, very small differences in equipment size may cause an LCD maker to choose one particular screen size vs. another. This is why TVs are often termed 42” (or some other size) class vs having every maker make a screen that is precisely 42”. Sometimes when it seems that the industry has settled on a standard size such as 40”, an individual LCD maker will determine that he can get the same number of cuts and consequently virtually identical costs, on a 42” or larger screen size and start offering that size. Even when the industry seems to standardize on sizes (32”, 40”, 55”) other sizes will proliferate. For a particular sized fab originally designed to make 12 cuts from a mother-glass, only certain sizes of larger screens will fit well on that equipment. In this example, trying to make a slightly larger screen may mean going from 6 cuts to 3.

Recently there was a story of some TV brands selling smaller than advertised TVs. The article tended to blame the retailers for the problem. However, large retailers sell multiple brands and multiple models; they cannot inspect every TV model to ensure that it is in compliance. Most Retailers actually do keep tape measures behind their TV counters; however this is mostly to ensure that the TV physically fits where the consumer is intending to place it. Short of actually measuring the screen diagonal yourself, the best guarantee that you are getting the screen size advertised is to buy a trusted name brand.